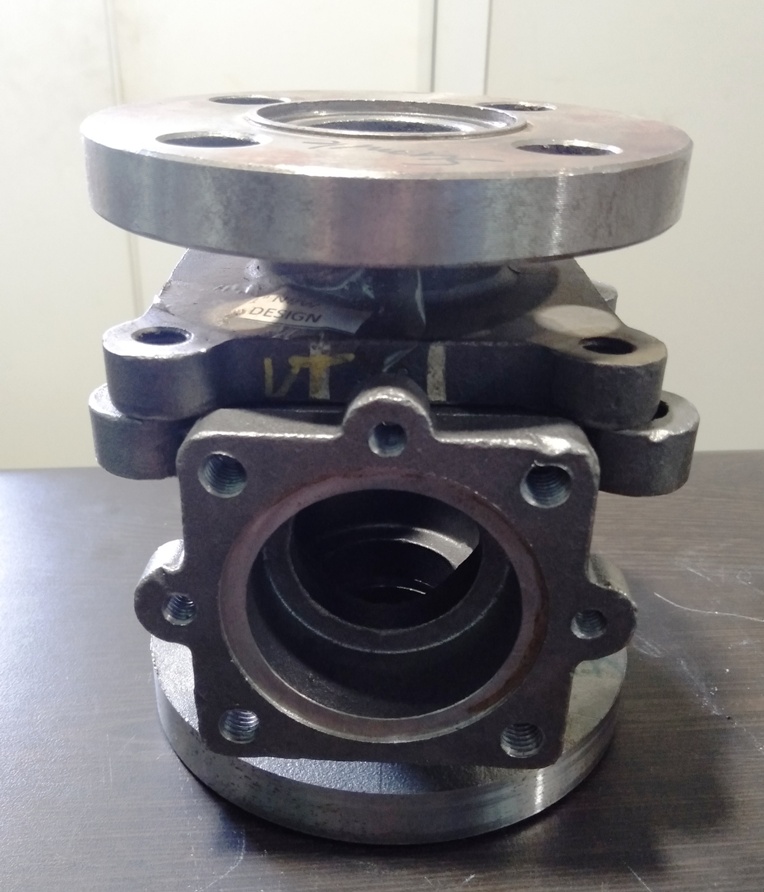

valve pump

flange valve

valve pump

Owing to the rich industrial experience and expertise in this domain, we are engaged in offering superb quality range of Die Casting Flange to valve flange. Our offered product is precisely manufactured valve pump in vadodara quality assured raw material and cutting edge technology. valve flange in vadodara Die Casting Flange is available at flange valve.

The manufacturing of the products is done by dedicated and enthusiastic professionals, who use modern tools and high grade raw material. The offered range of products is known to have an excellent quality and reliability. In addition to this, the offered products are delivered at market leading prices so that customers can fulfill their demands in a valve flange in vadodara.

valve pump The highly sophisticated and high-tech infrastructural facility has been flange valve with all the valve pump in vadodara and tools. This helps us in the attainment of a number of the firm’s goals and objectives in a stipulated valve flange.

valve pump

Valve, Pump Flanges offered feature precision design and construction finish and can be made available by us in different metal choices like stainless steel, carbon steel, alloy steel and others. Some of its features include different material choices like carbon steel, alloy steel, stainless steel, low temperature steel and others.

During the first decades of the wind energy development, wind turbine blades were often produced using the wet hand lay-up technology, in open molds. The valve flange in vadodara reinforcement was impregnated using paint brushes and rollers. The shells were adhesively bonded flange valve. This technology was used mainly to produce small and medium size blades valve pump. For larger blades

Thermoplastics represent an interesting alternative to the thermoset matrices. The important advantage of thermoplastic composites is their recyclability. Their disadvantages are the necessity of high processing temperatures (causing the increased energy consumption and possibly influencing fiber properties) and, difficulties to manufacture large valve pump in vadodara and thick valve pump in vadodara parts, due to the much higher viscosity.

Fibers for composites are being applied with a surface sizing often referred to as sizing. The application happens during or just after the manufacturing. The two main reasons to apply sizing is to protect the fibers and to increase bonding to the matrix. The adhesion between fiber and matrix is pivotal when it comes valve flange in vadodara fiber and matrix and the mechanical properties of the composite. The stress transfer happens not only between the fiber valve flange but across the sizing as well. Unfortunately the sizing and its reactions in the interface is barely understood due to the complexity and flange valve

Contact Info

+91-9725421076

+91-9714288779

info@unisoncorporation.in

About Company

We are a team of professional who were working with industries of repute in the fields like Precision Component Manufacturing, Injection Molding dies, machine tools , jig & fixture development.