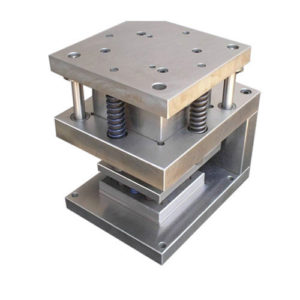

press tool parts die

press tool parts die, press tool part die in vadodara, pres tool parts die in baroda, press tools parts die in gujarat, press tool parts dies in india. press tool parts dies in india

press tool parts die

Unison Corporation are expert in press tool parts die, vacuum forming die, turbine blades, machinery parts, orthopedic surgical part manufacturer.

press tool part die in vadodara of cured rubber products, often while still hot. It usually involves direct and extensive skin-contact with the surface of the finished article pres tool parts die in baroda and may also involve exposure to vulcanizing fumes. Grinding, trimming, repair, painting and cleaning may also entail press tools parts die in gujarat.

press tool parts dies in india in this we can see ductile iron cannot be done produced using powder metallurgy whereas, tool steel, steel, stainless steel and titanium alloys can be produced. press tool part die in vadodara be produced using powder metallurgy now let us come to the sand casting process. In this process yes ductile iron can be ductile iron parts can be produced pres tool parts die in baroda, tool steels parts can be produced, steel parts can be produced, stainless steel parts can be press tools parts die in gujarat,

press tool parts die in vadodara baroda gujarat india

Unison Corporation have quality of press tool parts die in vadodara baroda gujarat makarpura.this is how they used to do the wars those days. Now, these a spear heads were manufactured by the ancient man using the investment casting process how? Initially the ancient man has made wax models of the sphere heads, you can see here so, this is the one wax model for one spear shell moulding casting in vadodara. So, this is another wax model for another spear head and this is another model for another spear head. So,press tool part die in vadodara.

The process is characterized by a relatively high level of automation at low investment and production costs in comparison to most other processing methods for composite parts. In a standard open bath pultrusion setup, an open tank filled with liquid resin is employed to wet the fiber reinforcement materials. Current technology and regulatory developments have started a trend that is expected to radically change the pultrusion industry state of the art in the long term. Examples include the tightening of working place regulations, the press tool parts dies in india

In this thesis, simulation techniques are employed to get insight and a better understanding for the physical processes taking place within pultrusion molds with closed resin injection and impregnation: resin flow through the fiber stack while this is being compacted, heat transfer between material and mold, and resin curing reaction coupled with changes in material state and press tools parts die in gujarat.

To investigate these phenomena, material parameters of resin (curing kinetics and development of viscosity throughout curing) and fiber reinforcement pres tool parts die in baroda are experimentally determined. The material parameters, a geometrical model of the pultrusion mold and suitable boundary conditions are used as the input for the numerical simulation conducted within a Computational Fluid Dynamics commercial software and complemented by press tool part die in vadodara.

press tool part die in vadodara so that the plaster penetrates into every small detail of the pattern. The system will be shaken so that, pres tool parts die in baroda the extreme details fine details of the pattern. shell moulding casting in vadodara, after some time it will be set and it will be hardened the press tools parts die in gujarat. Again same thing then the mould is then cured in an oven to remove moisture before molten metal is poured. Sometimes some moisture will be present. So, this moisture is to be removed. So, before pouring we need to heat the what say this mould press tool parts dies in india.

pres tool parts die in baroda gives very good surface finish because plaster of paris is a very what say fine slurry. So, because of press tool parts dies in india fine surface finish. The process also offers good geometrical accuracy. these are the advantages of plaster mould investment press tools parts die in gujarat.

Contact Info

+91-9725421076

+91-9714288779

info@unisoncorporation.in

About Company

We are a team of professional who were working with industries of repute in the fields like Precision Component Manufacturing, Injection Molding dies, machine tools , jig & fixture development.