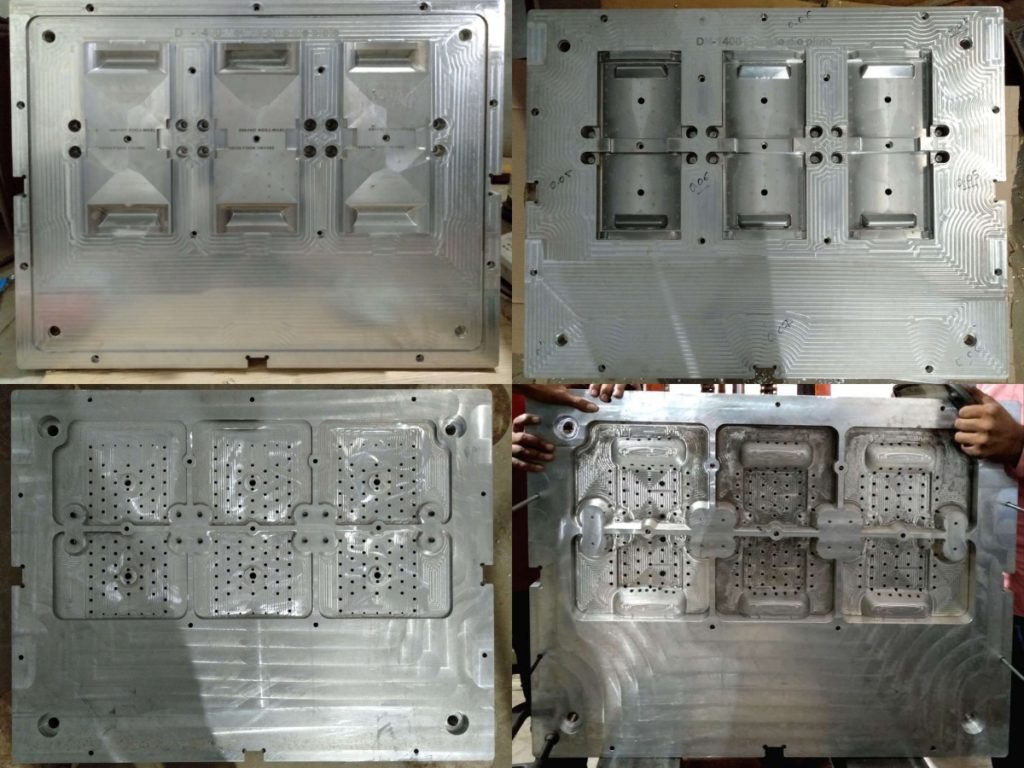

plastic moulding

plastic moulding, plastic moulding in vadodara

plastic moulding

Unison Corporation are expert plastic moulding, vacuum forming die, turbine blades, machinery parts, orthopedic surgical part manufacturer. pressure die casting.

In the mercast process solid mercury is used as the pattern material, generally wax is used as the pattern material in investment casting process. In fact, plastic moulding in baroda first to two processes we have discussed wax was used as the pattern material, but here this plastic moulding in vadodara.

So, that is the unique feature of mercast process even the name implies the same mercast means mercury is used in this casting process. mercury is drained out by raising its temperature followed by pouring of the molten metal. Once we raise the temperature or at least when we bring it to the room temperature, the mercury will be melting and it will be drained out from the shell. Then we can pour the molten metal into the shell.

plastic moulding in vadodara baroda gujarat makarpura

Unison Corporation have quality of plastic moulding in vadodara baroda gujarat makarpura. that way the process becomes expensive. Not only that, the mercury pattern itself is costly mercury itself is costly, that way the whole process becomes costly. So now a days, this process this mercast process is no more in use. Next one, ceramic shell investment casting process. So, this is the what say ceramic shell investment casting.

In the beginning, there will be a fine slurry will be there as the may be after fourth coating there will be coarse slurry will be there. So, first three coats it will be dipped inside the fine ceramic slurry, after third coating there will be a coarse slurry will be there. So, and even they stucco will be coarse are one. So, that as we going what say to the outwards the permeability of the shell will be increasing.

here we make the ceramic shell in this way by dipping into the what say ceramic slurry and applying this stucco finally, you see a shell is created, then we heat it the wax pattern inside this shell will be melting and it will be drained out then molten metal will be poured into this shell after solidification we can break that shell finally, we are getting the turbocharger rotor,

plastic moulding in vadodara can be cast that we have seen in the beginning itself any alloy can be cast which is not possible with other casting process including ones that are impossible to forge or plastic moulding in baroda. Any hard alloy, any soft alloy can be produced using investment casting process. Next one, castings are free from usual defects that are encountered in sand casting process.

Contact Info

+91-9725421076

+91-9714288779

info@unisoncorporation.in

About Company

We are a team of professional who were working with industries of repute in the fields like Precision Component Manufacturing, Injection Molding dies, machine tools , jig & fixture development.