orthopedic surgical part manufacturer

orthopedic surgical part manufacturer in baroda, orthopedic surgical part manufacturer in baroda

With our expertise and trustworthiness, we are engaged in offering an optimum quality range of orthopedic surgical part manufacturer A simplest example of open die forging is compression of billet between two flat die halves which is like compression test. This also known as upsetting or upset forging. Basically height decreases and diameter orthopedic surgical part manufacturer in vadodara. where there is no friction between the billet and die surfaces, homogeneous orthopedic surgical part manufacturer. In this, the diameter increases uniformly throughout its orthopedic surgical part manufacturer in baroda.

orthopedic surgical part manufacturer separate die cavities are required for shape change. In the initial stages, uniform distribution of properties and microstructure are seen. In the final stage, actual shape modification is observed. When drop forging is used, several blows of the hammer may be required for each step, In the intermediate stage, the initial billet deforms partially giving a bulged shape. During the die full closure, impression is fully filled with deformed billet and further moves out of the impression to form flash so orthopedic surgical part manufacturer in baroda.

orthopedic surgical part manufacturer Impression die forging is not capable of making close tolerance objects. Machining is generally required to achieve the accuracies needed. The basic geometry of the part is obtained from the forging process, with subsequent machining done on those portions of the part that require precision finishing like holes, threads etc. In these presses, the rotating motion of a drive motor is converted into the translation motion of the ram. They operate by means of eccentrics, cranks, or knuckle joints. Mechanical presses typically achieve very high forces at the bottom of the forging stroke in orthopedic surgical part manufacturer in vadodara,

orthopedic surgical part manufacturer in baroda is used to reduce the diameter of a tube or a rod at the end of the work piece to create a tapered section. In general, this process is conducted by means of rotating dies that hammer a workpiece in radial direction inward to taper it as the piece is fed into the dies. A mandrel is required to control theshape and size of the internal diameter of tubular parts during swaging also orthopedic surgical part manufacturer in baroda.

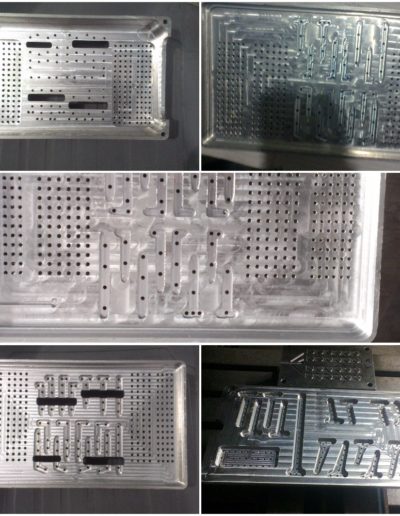

Sterile Box

Contact Info

+91-9725421076

+91-9714288779

info@unisoncorporation.in

About Company

We are a team of professional who were working with industries of repute in the fields like Precision Component Manufacturing, Injection Molding dies, machine tools , jig & fixture development.